Types of Concrete and Masonry Anchors and How to Use Them

Some ways to affix construction elements, such as blocks, equipment, piping, and ducting onto a concrete, wood or stone structure, is to nail, glue or screw them to the target surface. However, that technique is not always feasible – that’s where anchors come in. Professionals use anchors to fasten material together where nails, glue, and screws wouldn’t work.

Here are seven types of anchors you’ll typically come across when completing concrete and masonry projects. Each of them has unique characteristics you’ll need to understand. You’ll learn how to use concrete anchors and how to use masonry anchors to secure different materials. Your choice of which anchor to use depends on your understanding of the job at hand, and how specific anchors fit into those requirements.

Concrete Drop-In Anchors

These are used where the application involves concrete. Ideal for high-strength concrete installations, they work by attaching a threaded bolt or rod to the internally-threaded body of the anchor. Some varieties of concrete drop in anchors are available with a lip at the top of the anchor. The purpose of the lip is to ensure that the drop-in anchor does not drop too deeply into the concrete in which installation takes place.

For the best installation of drop-in anchors, professionals prefer to use a high-quality anchor setting tool, such as those available at Set It FAST Setting Tools.

Lag Shield Anchors

This type of anchor is comprised of two parts, a pre-assembled two-part expandable lag shield and a lag screw and is commonly used for high-strength applications. The anchors are designed for use with lag screws, which are combined to form an anchor into concrete, brick and block. When the lag screw is tightened into the shield, the shield expands inside the target area, thus providing a firm anchor mechanism.

Similar in principle and construction to drop-in anchors, lag shield anchors do not require an anchor setting tool.

Sammy's Hanging Anchors

When professionals are faced with a hanging application in wood, their anchor of choice is typically a Sammy’s hanging anchor – also known as a Sammy screw. “Sammy”, in this case is the name of a specific manufacturer. However, these types of hanging anchors are available from multiple other manufacturers. Sammy screws have a threaded opening, through which installers use threaded rods or bars, once the anchor is screwed onto the target location.

Typical use of Sammy’s hanging anchors are for plumbing and HVAC applications, as these are ideal for hanging pipes and ventilation ducting.

Drive Pin Anchors

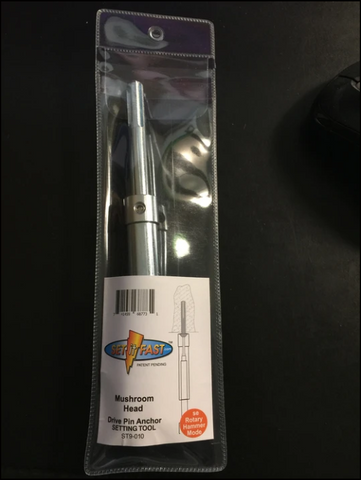

A drive pin anchor (also called a “Zamac”/ mushroom head anchor) is one of the most common anchors available in a professional’s toolbox. They come with a lipped head to protect the anchor from being driven too far into the pre-drilled home in the target material. Once dropped into the hole, the professional hammers the pin, at the top of the anchor, driving it into the anchor’s body. As the pin drives in, it expands the body of the anchor, causing a strong anchoring effect.

This type of concrete anchor is best installed using a professionally manufactured anchor setting tool, such as that available through Set It FAST Setting Tools.

Toggle Wing Anchors

Toggle wing anchors are best used when installers have to deal with a hollow wall application. Typically, this scenario presents itself when builders use cinder blocks to erect a structure. Toggle wing anchors are also the anchor of choice in drywall applications. This type of anchor is comprised of two parts, an expandable toggle and a bolt that’s threaded through the toggle.

The toggle part of the anchor is pushed through a hole drilled into the target structure. This causes the toggle to expand in the hollow structure. The bolt is then tightened, using an appropriate screwdriver, which causes the anchor to tighten onto the structure.

Wedge Anchors

Wedge anchors are one of the more popular types of anchors used for high-strength applications, typically for materials anchored in concrete. They are comprised of a bolt-like assembly with a sliding ring on the interior end that slides when the bolt is tightened in the concrete.

At the top of the anchor is a nut. The anchor is driven into a hole drilled into the concrete, and a washer is placed at the top. Next, the installer tightens the nut. This action pulls the ring at the far interior end of the anchor tightly into the concrete. This delivers a firm grip of the anchor into the concrete surface.

Sleeve Anchors

Installation is straightforward, with the anchor placed in a pre-drilled hole. The tightening of the nut pulls it (the nut) up into the anchor sleeve, expanding it and giving it a firm grip into the target surface. The only difference, between the Phillips/slotted combo driven flat head version and the nut drive model, is that the former mounts flush to the surface.

It’s All About Choice

As we’ve seen above, the type of anchor you choose depends on the anchoring application. On the other hand, since each application might vary in scope, there may be opportunities to choose from one or more types of anchors to accomplish the task. Regardless of how you go about making your decision to use a specific anchor, your choice of the right anchor will, however, determine success or failure of the job at hand.And, upon selecting your anchor of choice, there’s a lot at stake during installation too. Improper installations may result in risk to life (of the install crew, contractors, visitors to the premises, residents, tenants, customers) and property. A loose or wrongly installed anchor may also result in dislodging the anchored element, compromising the entire construction site.

That’s why masonry pros use the right anchor setting tools, such as the anchor setting tools from Set It FAST. It is the system of choice for professionals across trades, including masonry. These setting tools are durable and tough, and significantly reduce the risk of faulty anchor installations. See the full line of anchor setting tools here.